Vision & Mission

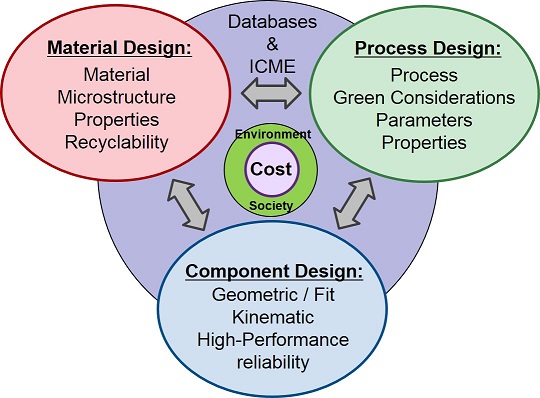

iMdc's vision and mission are to define, disseminate, and implement a new design paradigm and supporting methodologies for failure prevention and increased performance, reliability, and recyclability. Design is based on material-process-component integration for common and seamless utilization in high-integrity applications across all manufacturing sectors. Successful design integration is achieved through:

- Building connectivity within the field of Materials Science and ensuring material-process and material-material compatibilities

- Creating interdisciplinary bridges between Materials Science, Mechanical Engineering, Manufacturing, and other related disciplines and establishing material-properties-performance correlations

- Designing materials from a green processing perspective and incorporating recycling as a design factor

- Integrating knowledge across multi-scales, from nano to macro

- Transferring knowledge and lab experience to real structures

- Developing predictive analytical and computational design models validated by experimental data

- Developing and implementing NDE techniques for early damage detection and monitoring

- Constructing consistent and connective databases and reliability diagrams

- Providing advanced design tools and strategies, Roadmaps, for general use in all manufacturing industries and beyond.

The overarching objective of iMdcís research portfolio is to prevent failure and increase performance and reliability of high-integrity structures through:

- Exploring and advancing the fundamental and practical understanding of a wide range of multi-scale metallic and composite materials and their respective processes

- Developing new and optimized materials and processing practices

- Establishing knowledge-based microstructure-properties-performance relationships

- Providing practical integrative design tools and strategies, and

- Identifying and pursuing implementation venues for the developed materials, processes, and design methodologies.

Materials and processes are developed and optimized for enhanced fatigue, fatigue crack growth, fracture resistance including thermal and thermo-mechanical fatigue, wear, stress-corrosion and corrosion fatigue for high-integrity and fatigue critical applications. These include structural applications for transportation and other manufacturing sectors. Failure prevention by early and accurate in-situ damage detection before crack formation and subsequent crack monitoring using advanced NDE techniques (eddy current, resonant, etc.) are critically assessed and adapted for implementation in industrial settings. The research has significant emphasis on life-cycle engineering, green processing, and recycling. Regarding green materials and processing the interests are four-fold:

- Developing new materials and processes for increased recyclability and generating a New Metallurgy for recycled materials

- Developing effective and efficient sorting and recycling techniques

- Investigating the impact of increased utilization of recycled materials in high-performance materials and applications

- Redirecting certain recycled materials towards new applications.

The experimental track of all the research projects is complemented by a computational/modeling track. The research is multidisciplinary and interdisciplinary, and it integrates traditional and emerging research areas with great impact on the Future of Materials Science and Engineering and Sustainable Manufacturing.

iMdcís research program includes three types of research projects:

- Pre-competitive fundamental research projects funded by the consortium members

- Specific and proprietary (one-on-one) research projects conducted for the iMdc members

- Large-scale research projects funded by the federal government or foundations complementing and extending iMdcís research programs

iMdcís research programs are carried out by M.S./Ph.D. students, Post-Doctoral Fellows, or Research Associates and the developments are presented to the consortium members at two annual meetings, one in Spring and one in Winter. The meetings provide a technical forum while facilitating permanent interaction and communication between various participating members/industries. The centerís vision is further disseminated through presentations at technical conferences, panel discussions, invited lectures, workshops, professional association meetings, and internal corporate meetings.

iMdc faculty and research staff have interdisciplinary interests and expertise facilitating collaboration between various departments and programs at WPI. iMdc has also established liaisons and research relationships with other universities in the U.S. and Canada.

Maintained by webmaster@wpi.eduLast modified: Feb 04, 2019, 21:14 UTC