ur recent research at WPI has

concentrated on the use of computational fluid dynamics calculations to solve for the steady-state 3D flow

fields in model fixed beds, with associated transport and reaction. ur recent research at WPI has

concentrated on the use of computational fluid dynamics calculations to solve for the steady-state 3D flow

fields in model fixed beds, with associated transport and reaction.

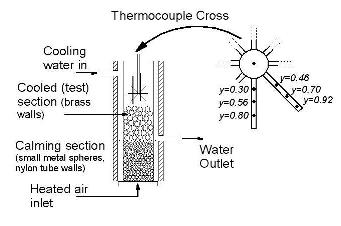

A major role of the experimental program lately has

been to provide data that can be used to check the simulation results. We have carried out such validation studies

to compare the CFD simulations directly to experimental data. In an early effort,

[Nijemeisland, M. and Dixon, A.G., 2001] a packed bed of spheres

with N = 2 was chosen, as this specific ratio allowed for a very structured bed in which the positions of all spheres

could be known precisely. This specific geometry was used for an experimental setup

and for the CFD simulations. Standard heat transfer experiments were carried out which gave radial temperature

profiles. Numerical simulations were performed under similar conditions to those under which the experiments were performed. The CFD

simulations gave 3D axial, radial and tangential velocity fields, as well as the 3D temperature field. For a range

of relatively low Reynolds numbers (373-1922) radial temperature profiles above the bed were extracted from the simulation results,

and these were directly compared with experiment at steady state conditions. The comparison of the temperature profiles

showed that CFD could qualitatively and quantitatively predict experimental results accurately for this geometry.

A major role of the experimental program lately has

been to provide data that can be used to check the simulation results. We have carried out such validation studies

to compare the CFD simulations directly to experimental data. In an early effort,

[Nijemeisland, M. and Dixon, A.G., 2001] a packed bed of spheres

with N = 2 was chosen, as this specific ratio allowed for a very structured bed in which the positions of all spheres

could be known precisely. This specific geometry was used for an experimental setup

and for the CFD simulations. Standard heat transfer experiments were carried out which gave radial temperature

profiles. Numerical simulations were performed under similar conditions to those under which the experiments were performed. The CFD

simulations gave 3D axial, radial and tangential velocity fields, as well as the 3D temperature field. For a range

of relatively low Reynolds numbers (373-1922) radial temperature profiles above the bed were extracted from the simulation results,

and these were directly compared with experiment at steady state conditions. The comparison of the temperature profiles

showed that CFD could qualitatively and quantitatively predict experimental results accurately for this geometry.

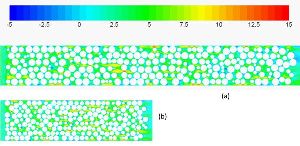

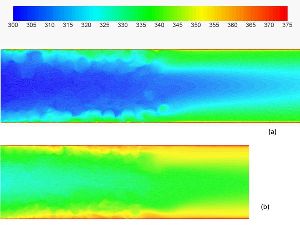

In a more recent study designed to reach the Reynolds number ranges more typical of steam reforming, the experimental part was conducted

at the Johnson Matthey facilities in Billingham, UK. One of our undergraduates was seconded there over a 10-week period in summer ’10,

and worked with Johnson Matthey engineers to perform heat transfer experiments on a large-scale industrial rig at higher gas velocities

and bed depths than are obtainable in an academic laboratory setting. These were then used to validate full tube CFD models for flow (left) and

heat transfer (right), which were developed at WPI to simulate the experimental runs. The comparisons were made for particle Reynolds numbers

in the range 2200 < Re < 27000 for tube-to-particle diameter ratio N = 5.45 (a), and in the range 1600 < Re < 5600 for N = 7.44 (b). The CFD

simulations compared well to the experimental data: trends with Re, N and bed depth were captured, and quantitative agreement of the

temperature profiles was very reasonable [Dixon, A.G., Walls, G., Stanness, H., Nijemeisland, M.,

and Stitt, E.H., 2012].

In a more recent study designed to reach the Reynolds number ranges more typical of steam reforming, the experimental part was conducted

at the Johnson Matthey facilities in Billingham, UK. One of our undergraduates was seconded there over a 10-week period in summer ’10,

and worked with Johnson Matthey engineers to perform heat transfer experiments on a large-scale industrial rig at higher gas velocities

and bed depths than are obtainable in an academic laboratory setting. These were then used to validate full tube CFD models for flow (left) and

heat transfer (right), which were developed at WPI to simulate the experimental runs. The comparisons were made for particle Reynolds numbers

in the range 2200 < Re < 27000 for tube-to-particle diameter ratio N = 5.45 (a), and in the range 1600 < Re < 5600 for N = 7.44 (b). The CFD

simulations compared well to the experimental data: trends with Re, N and bed depth were captured, and quantitative agreement of the

temperature profiles was very reasonable [Dixon, A.G., Walls, G., Stanness, H., Nijemeisland, M.,

and Stitt, E.H., 2012].

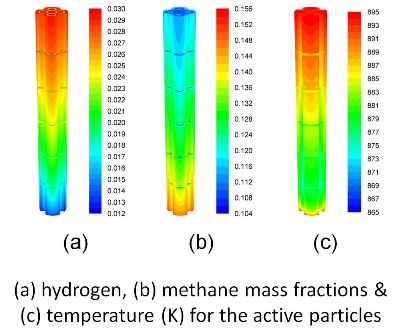

We have also made a combined experimental and CFD validation study under reacting conditions, the experimental parts were again

conducted at the Johnson Matthey facilities in Billingham, UK. A graduate Ph.D. student was seconded there over the same 10-week period in

summer ’10. The experimental work of the graduate student was a study of heat transfer inside catalyst pellets undergoing steam reforming

reactions, for validation of the methodology for incorporating reactions into solid particles in CFD. Commercial Ni/alumina catalyst pellets

were used in a single-pellet string microreactor, under typical steam reforming conditions and also conditions intended to promote carbon

deposition and deactivation of the catalyst. Thermocouples were placed inside various catalyst pellets to be able to measure the temperature

changes inside the reacting pellets. A computational fluid dynamics (CFD) model was used to predict temperature and species profiles under the

experimental MSR reaction conditions. Comparison of CFD and experimental data showed very good qualitative as well as quantitative agreement

for temperature inside catalyst particles at different inlet gas temperatures, and for the temperature drop from outside to inside the pellets

due to the reaction heat sink. Trends in methane conversion were also well-represented.

[Behnam, M., Dixon, A.G., Wright, P.M., Nijemeisland, M., and Stitt, E.H., 2012].

We have also made a combined experimental and CFD validation study under reacting conditions, the experimental parts were again

conducted at the Johnson Matthey facilities in Billingham, UK. A graduate Ph.D. student was seconded there over the same 10-week period in

summer ’10. The experimental work of the graduate student was a study of heat transfer inside catalyst pellets undergoing steam reforming

reactions, for validation of the methodology for incorporating reactions into solid particles in CFD. Commercial Ni/alumina catalyst pellets

were used in a single-pellet string microreactor, under typical steam reforming conditions and also conditions intended to promote carbon

deposition and deactivation of the catalyst. Thermocouples were placed inside various catalyst pellets to be able to measure the temperature

changes inside the reacting pellets. A computational fluid dynamics (CFD) model was used to predict temperature and species profiles under the

experimental MSR reaction conditions. Comparison of CFD and experimental data showed very good qualitative as well as quantitative agreement

for temperature inside catalyst particles at different inlet gas temperatures, and for the temperature drop from outside to inside the pellets

due to the reaction heat sink. Trends in methane conversion were also well-represented.

[Behnam, M., Dixon, A.G., Wright, P.M., Nijemeisland, M., and Stitt, E.H., 2012].

Since 2008, our group has carried out various experimental studies on packings of different shapes and sizes, using a

modified experimental set-up in which pre-heated air is cooled in a fixed bed equipped with a water-cooling jacket.

Our experiments in earlier years were done in an experimental setup in which cold air

was heated in a steam jacket. These were discontinued when the laboratory steam supply became seasonal.

Currently, both types of experiments are possible in the same equipment depending on the availability of laboratory

steam. This is allowing some interesting comparisons of heating and cooling experiments for the same packings over

similar ranges of flow rates, as well as studies of particle shapes for which there are still not yet any reports in

the open literature. These studies are mainly done by undergraduates as their senior year major qualifying projects.

Since 2008, our group has carried out various experimental studies on packings of different shapes and sizes, using a

modified experimental set-up in which pre-heated air is cooled in a fixed bed equipped with a water-cooling jacket.

Our experiments in earlier years were done in an experimental setup in which cold air

was heated in a steam jacket. These were discontinued when the laboratory steam supply became seasonal.

Currently, both types of experiments are possible in the same equipment depending on the availability of laboratory

steam. This is allowing some interesting comparisons of heating and cooling experiments for the same packings over

similar ranges of flow rates, as well as studies of particle shapes for which there are still not yet any reports in

the open literature. These studies are mainly done by undergraduates as their senior year major qualifying projects.

|